Product Description

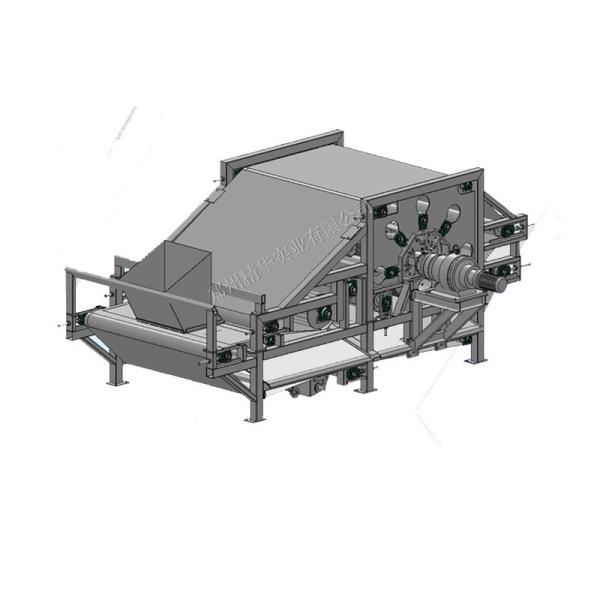

Fiber Dehydrator Description

Fiber dehydrator is used for dehydration of fiber in starch

industry. Mainly used in sweet potato starch, tapioca starch,

potato starch, wheat starch, corn starch, pea starch (starch

suspension) starch production enterprises.

Technical parameters of fiber dehydrator

Model | Power (Kw) | Filtrating strap width (mm) | Filtrating strap speed (m/s) | Capacity(Before dehydrated)(kg/h) | Dimension (mm) |

DZT150 | 3.3 | 1500 | 0-0.13 | ≥5000 | 4900x2800x2110 |

DZT180 | 3.3 | 1800 | 0-0.13 | ≥7000 | 5550x3200x2110 |

DZT220 | 3.7 | 2200 | 0-0.13 | ≥9000 | 5570x3650x2150 |

DZT280 | 5.2 | 2800 | 0-0.13 | ≥10000 | 5520x3050x2150 |

Advantages of fiber dehydrator

1. Product is independently developed by company, with the

scientific research efforts of Henan University of Technology.

2. Wedge-shaped feeder can ensure materials evenly distributed on

the filtrating strap with thickness being adjustable.

3. Dehydrated rolling system made seamless tube and wrapped by high

quality wear-resistant rubber, It`s reliable with long service

life.

Our Services

Pre-sale service

1. Introducing detail features and application of the products to

customer.

2. Selecting economical and practical machines for customer.

3. Providing operation data of the related machine.

4. Providing means of trial performance for customer.

5. Flow chart and factory designing layout .

On-Sale service

1. Recommending engineering conditions required for installation of

the machine.

2. Communicating the manufacturing progress of machines with

customer in time.

3. Project planning and design services.

After-sale service

1. Training of equipment maintenance and operating personally.

2. Installation and commissioning of equipment until everything is

functional.

3. One year warranty and Providing long-term maintenance service

and spare parts.

4. Giving technical support to customer for developing new product.

5. Engineers available to service machinery overseas.

6. Provide English Version of

Installation/Operation/Service/Maintenance Manual.

FAQ

Q1: Is your company a factory or a trading company?

A: Our company is a factory in Henan Province with export license,

and we have been specialized in export business for more than 20

years.

Q2. What is your main business?

A: Zhengzhou Jinghua is dedicated to starch processing machinery.

Starch processing line machines, such as: tapioca starch line,

tapioca flour line, potato starch line, sweet potato line, wheat

starch, sago line and garri line

Q3: Where is your factory located? How can I get there?

A: Our address: the intersection of Zhengyun Road and Guanggu Road,

Guangwu Town, Zhengzhou City, Henan Province, China.

Q4: Can your products be assured?

A: Our machines all have CE certificates from SGS, TUV.

Q5: If we show you our factory layout, can you help us design the

whole production line?

A : Yes, our experienced engineers and technicians can help you

arrange the layout and installation of the entire production line

according to your actual situation;

Q6: If we have samples of new products, can you help us analyze and

design the machine?

A: Yes, our technical department can help you analyze, design and

test the new products you offer.